Open Circuit Cooling Towers

What Makes a Tower Tech Open-Circuit Tower the Superior Choice?

Tower Tech's modular cooling towers are the highest-quality towers available on the market. With the best-in-class operational expenses of any cooling tower, a Tower Tech cooling tower has the lowest total cost of ownership. It also requires less maintenance and uses less water and chemical resources than conventional cooling towers, all while maximizing real estate and avoiding Legionella bacteria and corrosion. Our open-circuit tower provides redundancy that exceeds N+1 requirements.

Our open-circuit cooling tower, as the name suggests, has a unique thermal transfer design that rejects heat into the atmosphere through direct contact of the process water with the air. The heat exchange system cools the water in the tower via innovative fan placement and internal components to channel the air. As the water moves down through our towers, it encounters multiple, patented features that maximize efficiency.

BROWSE OUR OPEN-CIRCUIT COOLING TOWERS

Key Components of Tower Tech's Open Loop Towers

-

Variable Flow Rotary Nozzles

Our patented water nozzle designs distribute the water in a square pattern over the tower’s fill media to use the full surface area and cool more efficiently while avoiding clogs.

.jpg)

-

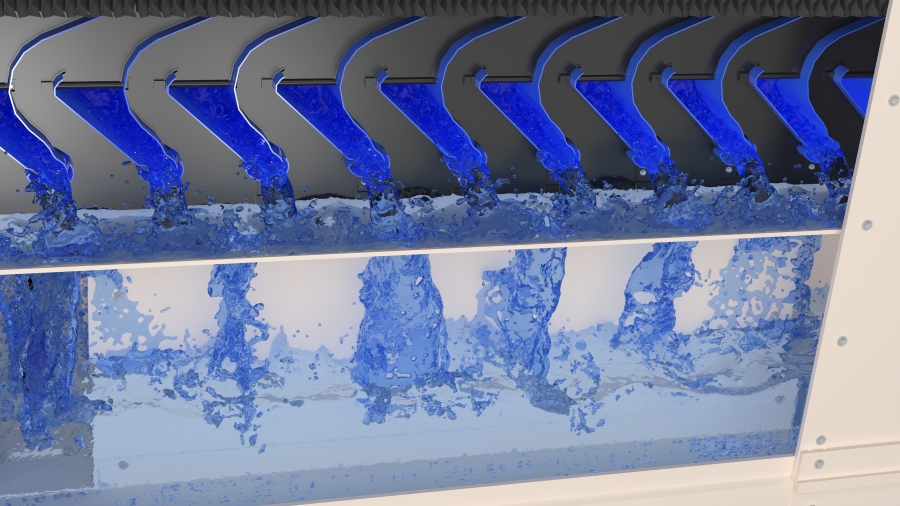

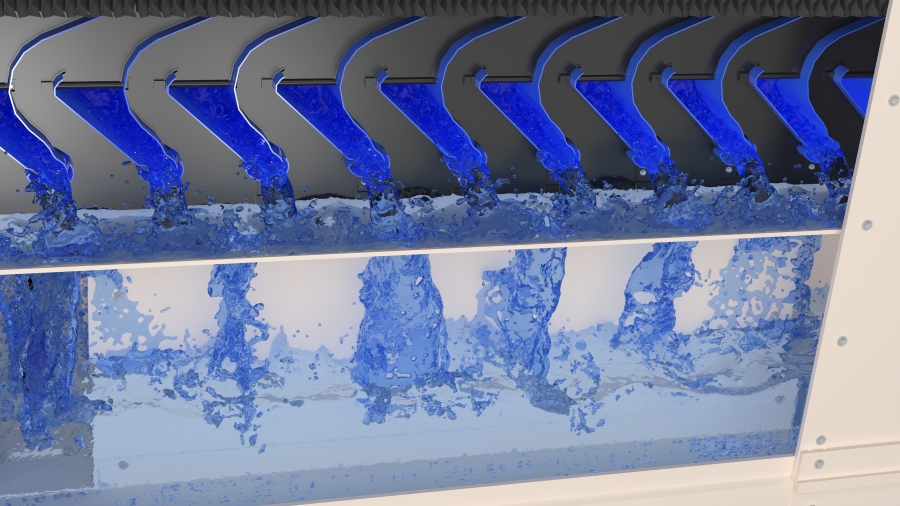

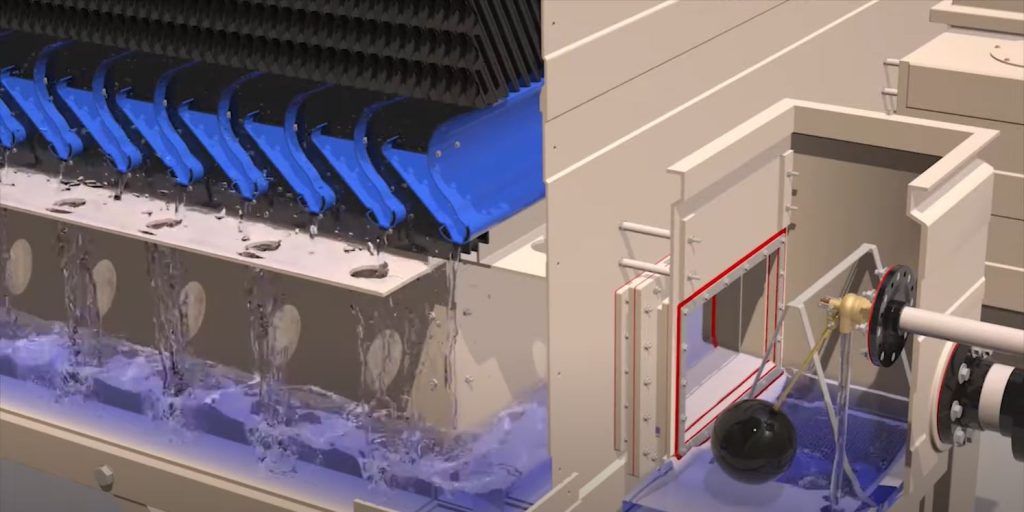

Water Collection System

Tower Tech's patented water collector system moves inlet air into the fill media and channels water flow into the FlowThru™ Basin while providing a leak-free barrier. This protects the tower's mechanical components, allowing the motors to be placed at the bottom of the cooling tower and allowing for easy, ground-level maintenance.

-

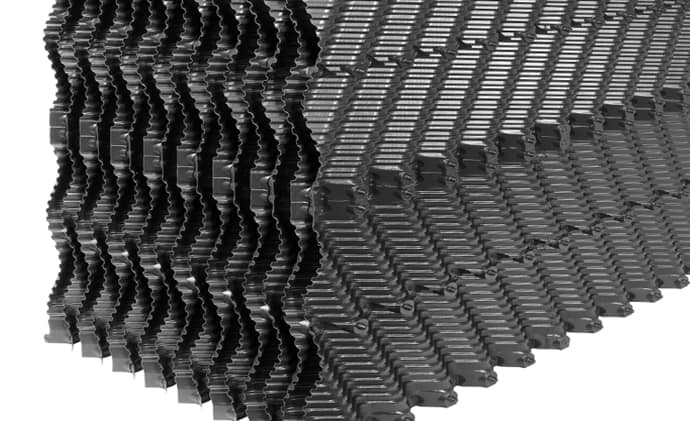

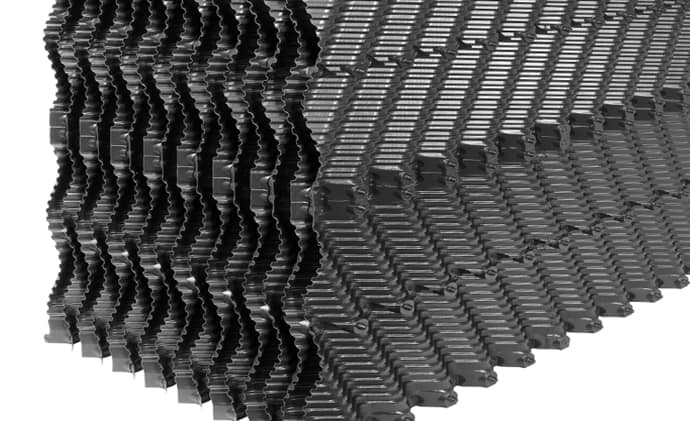

XchangeTech™ Fill Media

Tower Tech's OEM fill media uses a unique water fall technology that optimizes the heat exchange surface are via materials design and engineered air/water patterning. The cross-corrugated PVC film is designed to operate under most thermal, process and water quality conditions while resisting biological and chemical degradation.

-

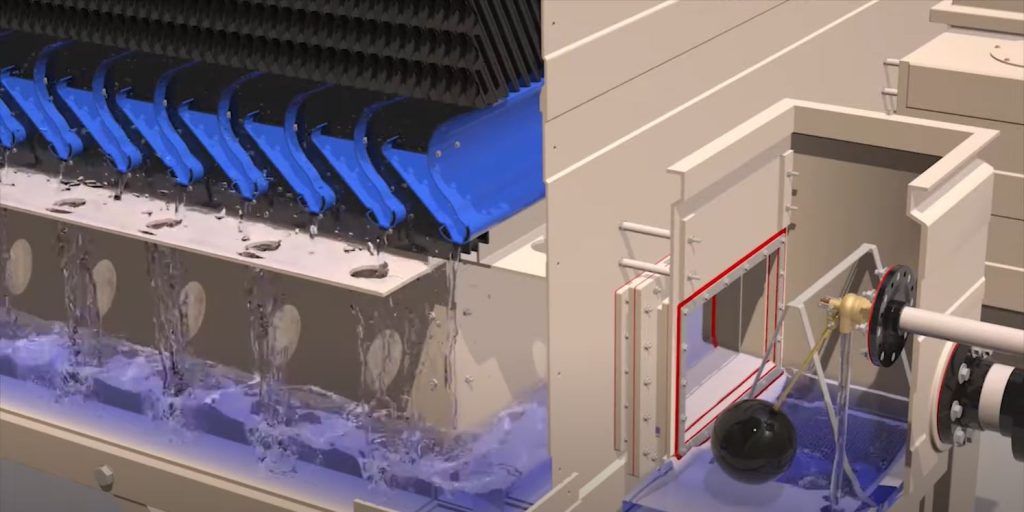

FlowThru™ Basin

Unlike the low velocity, cold water, settling basins common to conventional cooling tower designs, this patented basin has high water velocities in the channel that continually scrub the walls and floor to eliminate the build-up of sediment and potentially bio-hazardous material. The enclosed design eliminates any contact with sunlight, which stops algae and other biological growth. This reduces chemical use and mitigates the risk of deadly Legionella.

-

Bottom-Mounted Direct Drive Fans

Ambient air is pushed up through the tower to perform the cooling process. Tower Tech uses a series of smaller fans that increase the efficiency of our open loop towers and add redundancy to maintain uptime. The cool intake airstream protected from the elements and easily accessible at ground level, compared to the traditional side- or top-mounted fan design.

-

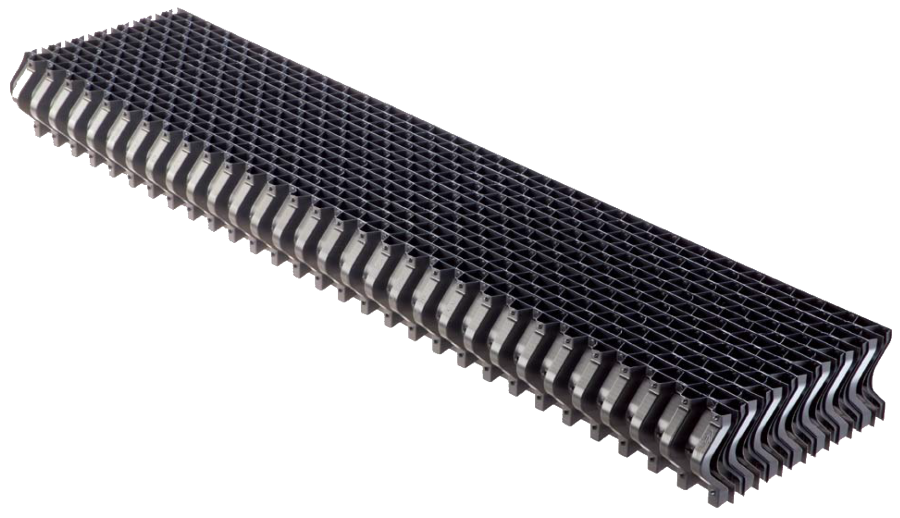

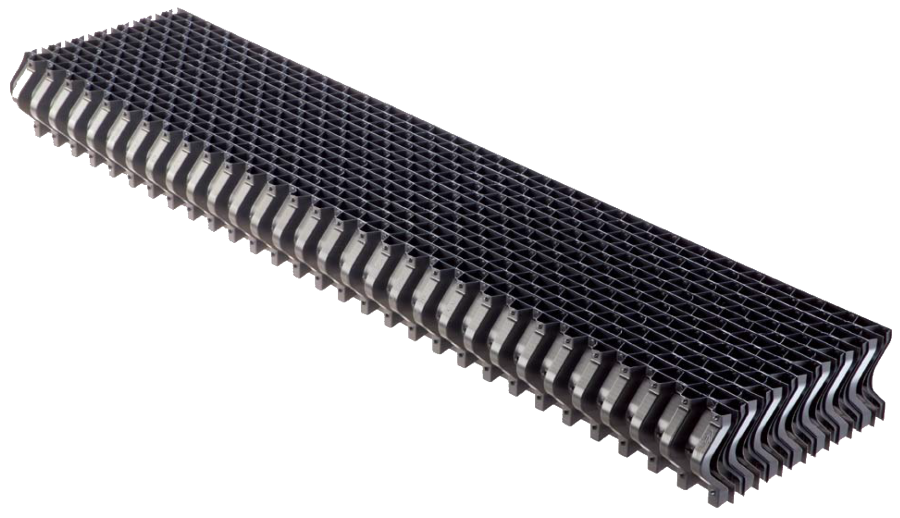

Drift Eliminator

Perhaps Tower Tech’s best-known efficiency story, our drift eliminator captures water that escapes the tower as mist in the air. The final drift rate of a Tower Tech tower is an industry-best 0.0004%.

Variable Flow Rotary Nozzles

Our patented water nozzle designs distribute the water in a square pattern over the tower’s fill media to use the full surface area and cool more efficiently while avoiding clogs.

.jpg)

Water Collection System

Tower Tech's patented water collector system moves inlet air into the fill media and channels water flow into the FlowThru™ Basin while providing a leak-free barrier. This protects the tower's mechanical components, allowing the motors to be placed at the bottom of the cooling tower and allowing for easy, ground-level maintenance.

XchangeTech™ Fill Media

Tower Tech's OEM fill media uses a unique water fall technology that optimizes the heat exchange surface are via materials design and engineered air/water patterning. The cross-corrugated PVC film is designed to operate under most thermal, process and water quality conditions while resisting biological and chemical degradation.

FlowThru™ Basin

Unlike the low velocity, cold water, settling basins common to conventional cooling tower designs, this patented basin has high water velocities in the channel that continually scrub the walls and floor to eliminate the build-up of sediment and potentially bio-hazardous material. The enclosed design eliminates any contact with sunlight, which stops algae and other biological growth. This reduces chemical use and mitigates the risk of deadly Legionella.

Bottom-Mounted Direct Drive Fans

Ambient air is pushed up through the tower to perform the cooling process. Tower Tech uses a series of smaller fans that increase the efficiency of our open loop towers and add redundancy to maintain uptime. The cool intake airstream protected from the elements and easily accessible at ground level, compared to the traditional side- or top-mounted fan design.

Drift Eliminator

Perhaps Tower Tech’s best-known efficiency story, our drift eliminator captures water that escapes the tower as mist in the air. The final drift rate of a Tower Tech tower is an industry-best 0.0004%.

Common Questions about Open Circuit Cooling Towers

-

Warm process water comes into contact with ambient air in the tower. This causes a portion of the water to evaporate, effectively reducing its temperature. The process is somewhat similar to blowing on a hot bowl of soup to cool it faster.

-

The primary difference is how the cooling process is handled. Open circuit systems allow direct contact between process water and ambient air, while closed circuit systems use a heat exchanger to separate the process fluid from the external environment. Closed circuit towers are important for industries that require the strictest purity, like hospitals, or require precise, constant temperatures with no water escape, like data centers.

-

Calculating initial expense is only the smallest part of a tower's total life cycle costs. Tower Tech provides the lowest total cost of ownership and best return on investment in the cooling tower industry. Our proprietary analytical software tool creates a PACE report to substantiate the savings. Our innovative technology saves more valuable resources than any other cooling tower through reduced:

- Fan and pump energy

- Water usage

- Chemical treatment

- Installation materials, labor and cost

- Maintenance

- Environmental impacts

- Lifetime carbon footprint

-

Open circuit cooling towers have efficiency and cost benefits. By using evaporation, cooling happens via a natural process, rather than through energy-intensive compressors or refrigeration systems. They are also somewhat more water-efficient than a closed circuit tower. Their relative simplicity makes them an often more cost-effective capital expense (CAPEX) and operational expense (OPEX) piece of equipment.

-

Open circuit towers are generally suitable for a wide range of climates. However, they may be less efficient in extremely humid conditions where the potential for evaporation is reduced. They can also experience freezing in very low temperatures if the tower is designed with an open louver or basin.

-

Regular monitoring, chemical treatment and annual or biannual cleaning is essential to prevent scaling, corrosion and biological growth. Annual preventative maintenance is key to maintaining optimal performance and to avoiding emergency repairs.

-

Common maintenance practices include regular inspections and cleaning of fill media, drift eliminators and the water collection system. It is also important to monitor water quality and chemical treatment levels. Most components can be safely inspected at ground level while a full tower health check should be conducted on an annual basis to ensure optimal performance.