TTCC Hybrid Fluid Series Closed Circuit Modular Cooling Towers

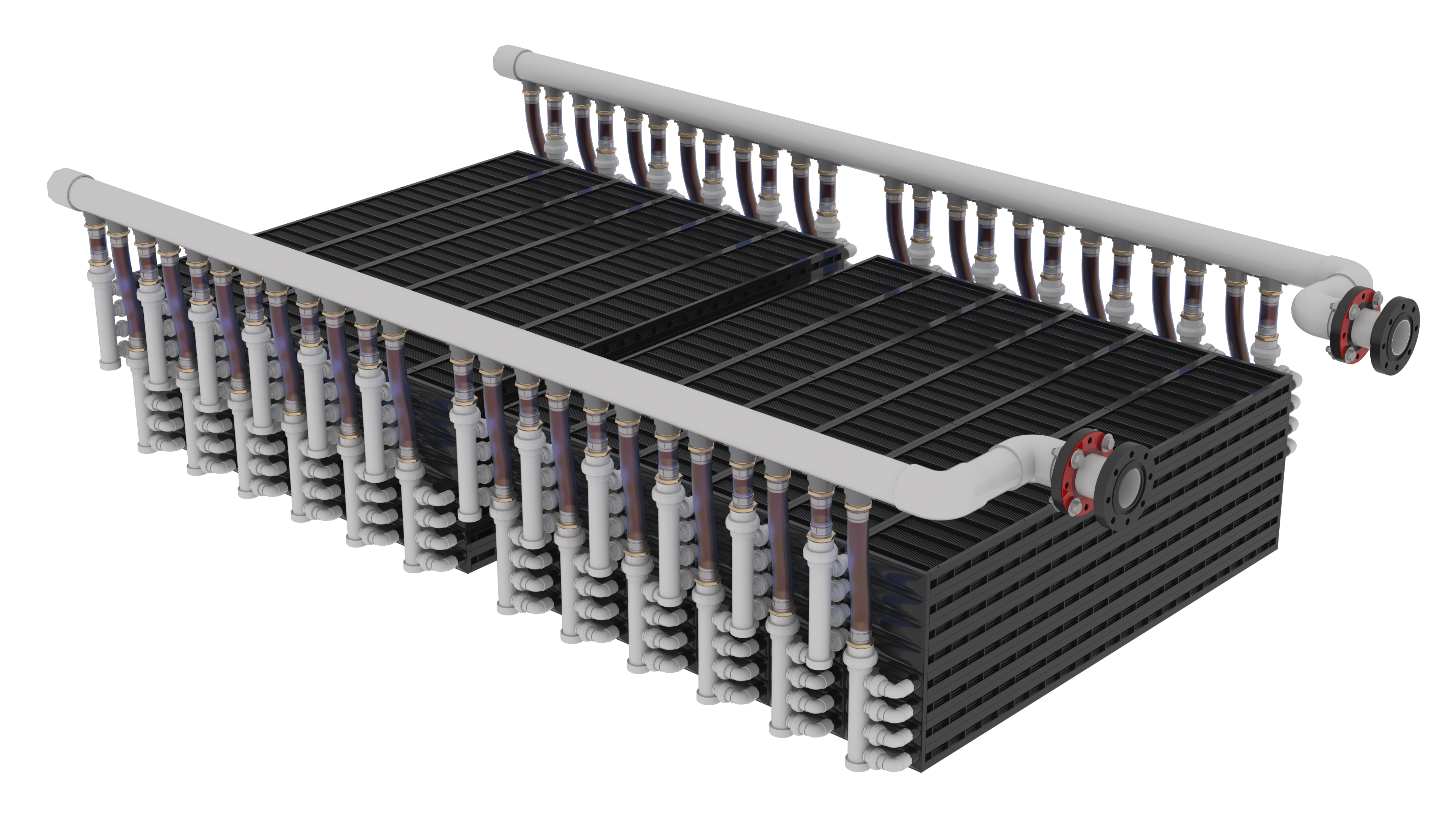

The TTCC-HC modular cooling tower was specifically engineered for applications that require a closed loop system that maximizes performance for clean process water and operation in fluctuating ambient conditions.

The TTCC-HC is a versatile solution for most applications from HVAC to industrial process systems. The hybrid fluid cooler minimizes energy, maintenance, water and installation costs while improving system reliability. The TTCC-HC is an excellent choice for critical operations where redundancy is a priority or water is a critical resource and is backed by an industry-leading, 15-year limited warranty.

Like all Tower Tech models, the TTCC models prioritize increased performance at design conditions, a smaller footprint with less water, energy and chemical use. The modular design makes it a versatile solution: modules can be interconnected in nearly any configuration to create virtually any size cooling capacity and easily accommodates future expansion.

Get Product Support

Hybrid Fluid Cooler Design

The TTCC-HC features fill media for wet mode operation in addition to coils to maximize the thermal heat transfer for optimum performance. It also comes with a factory-installed smart control package for the most sustainably efficient operations that can be connected to any digital management system.

The TTCC-HC shares Tower Tech’s unique design, creating an aesthetically pleasing product that typically blends into the surrounding structures and environment. Tower Tech cooling towers’ patented modularity allows units to be placed right next to each other in virtually any configuration saving your valuable real estate. These towers are prefabricated from the highest quality Fiber Reinforced Polymer (FRP) to be lightweight and to significantly decrease installation time and effort.

-

Fully Enclosed FlowThru™ Basin

-

Variable-Flow 2″ Spray Nozzle

-

Innovative Water Collection System

-

XchangeTech Fill Media

-

Bottom-mounted Direct Drive Fans

-

Factory Assembled Modular Design

-

Completely Corrosion-resistant Composite Construction with XchangeTech polymer coils

Hybrid Operation

The TTCC-HC uses a heat exchanger coil to cool the process fluid in hot and humid conditions, and a dry coil to cool the process fluid with ambient air in cooler and drier conditions. This combination allows the hybrid cooler to operate efficiently and effectively throughout the year.

Tower Tech modular cooling towers are the most operator-friendly cooling towers with the lowest maintenance requirements on the market. The TTCC-HC uses standard 2″ Rotary Spray Nozzles that provide reliable, clog-free operation with a minimal pressure requirement of less than 1.2 psi. The TTCC-HC design can be operated in a wet or dry mode to save water and energy throughout the year. The closed circuit design keeps the system contaminant-free and uses far less water and chemicals. The TTCC-HC cooling tower can also take advantage of ambient temperatures during the year.

TTCC-HC Benefits

- Lightweight, corrosion-resistant XchangeTech polymer coils have excellent thermal performance compared to metal exchangers and a much longer service life

- The recirculating pump automatically cleans the tower and coils, which reduces scale to decrease needed maintenance and chemical use and to increase performance

- The pre-engineered, certified substructure reduces infrastructure cost

- Patented heat transfer design, variable flow nozzles and multiple direct drive motors provide the highest efficiency, lowering system energy requirements and fan motor and pump horsepower

- Qualified for LEED points and energy rebates

- Essential parts have built-in redundancy to increase reliability and uptime

- All scheduled inspections and routine maintenance can be safely performed at ground level

- The Tower Tech series modular towers offer the lowest drift rate on the market at 0.0004%. This can save up to 80% water savings compared to conventional tower designs

- The factory-preassembled modular design allows for quick installation in less than 30 minutes

- This drift rate combined with the Flow-Thru Basin™ and closed circuit tower design significantly reduces water usage and chemical treatment costs

- Tower Tech towers have the longest lifespan of any factory-preassembled cooling tower (over 30 years) and have an industry-best, 15-year limited warranty

- All Tower Tech cooling towers are made with StormStrong™ technology and are certified to withstand hurricane-force winds and worse

- Tower Tech's design eliminates unsightly fan stacks, louvers, rust and algae growth. The natural beige color blends in well with most environments and buildings, or a logo or graphic design wrap may be easily added

- 100% made in the USA in an ISO 9001 facility

XchangeTech™ Polymer Coils Change the Game

How could a polymer heat exchanger be effective? Because of its low thermal resistance, polymers transfer heat with great effectiveness.

Thermal resistance is based not only on conductivity (k) but also on surface area (A) and wall thickness (t). Thermal resistance is calculated by dividing thickness by conductivity times surface area.

Using this formula, Tower Tech has created our polymer heat exchangers, XchangeTech Coils, that function equivalently to their metal competitors. A small diameter tube with a thin wall minimizes thermal resistance. Hundreds of these tubes – 440, to be exact – are bundled together to provide a large primary surface area for heat transfer.

How do these polymer coils change the game? Polymer heat exchangers are extremely lightweight, which makes installation simpler, faster and safer while providing a very low internal pressure drop. And because they are polymer, they cannot rust or corrode, which means they outlast most metal coils. They also have a superior impact resistance, as there are no thin fins to ben or impede performance, and they are compatible with water, glycols, brine, chlorides, oils and more.