The number may shock you: Many businesses are wasting thousands or even tens of thousands of dollars each year by defaulting to traditional cooling towers with open sediment basins.

The difference between a traditional open basin and Tower Tech’s enclosed FlowThru™ basin is like comparing the amount of water in an Olympic-sized swimming pool (660,000 gallons) versus the average-sized in-ground backyard pool (17,435 gallons). We’re talking about 3,000% less water in comparison. This visual is a great way to think of Tower Tech’s minimal water basin as compared to some of the behemoth basins used in the industry.

Why are traditional basins so much less efficient than Tower Tech’s FlowThru basin? Let’s take a closer look.

Traditional Sediment Basins

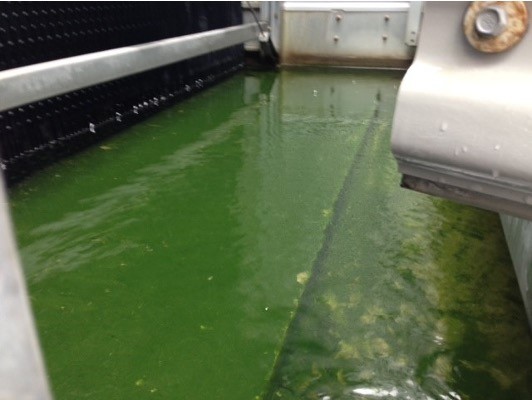

Conventional cooling towers rely on a “sediment” basin, a large catch-pool or basin that holds a large water volume. This takes up a lot of water and space and leaves the basin open to a number of problems like sediment accumulation in the corners, with photosynthesis that yields algae which feeds Legionella and have a typical drift emission of 0.002%. This obvious problem is known to the traditional cooling tower makers and essentially have taken a band-aid approach to solve this problem by adding what is known as “basin sweepers” to agitate the water and sediment in the basin so as to minimize sediment accumulation. This poorly conceived approach in reality only adds more pumping costs to the cooling tower operations costs and another set of nozzles that can also plug in the nasty environment of the murky basins.

Conventional towers cannot survive the corrosive conditions of seawater and have a poor impact on increased cycles of concentration. Keeping the water in these towers at the right levels means lots of water costs and keeping that water safe means lots of chemicals and maintenance. More hardware, more money, more risk. These water basins are the source of many of the environmental problems of cooling towers. In some less than flattering critiques, these open sediment basin designs have sadly been referred to as “legionella gardens” which sadly has been true far too many times.

Tower Tech’s FlowThru Basin

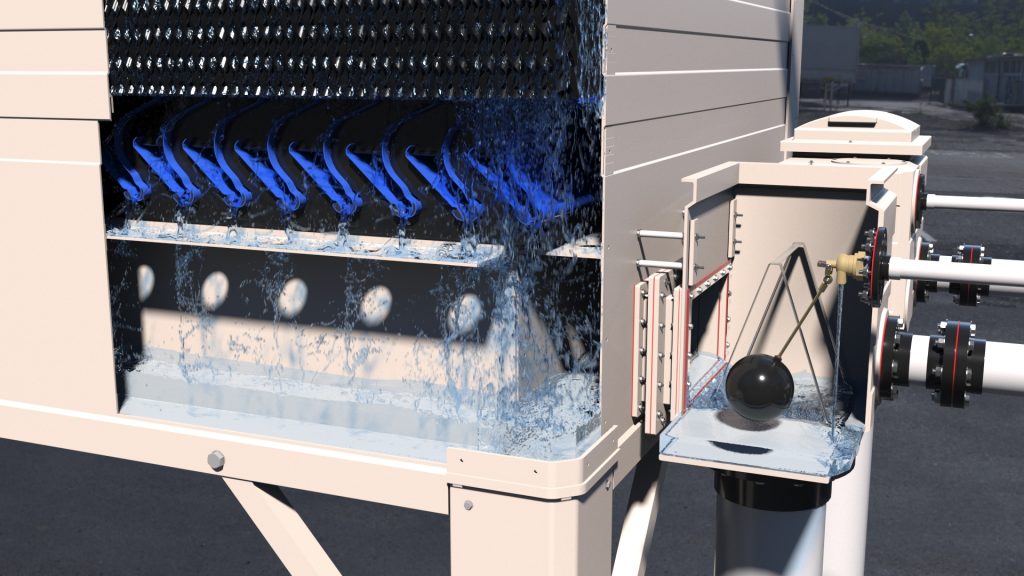

The FlowThru basin is Tower Tech’s proprietary enclosed flow-through basin where the water is constantly moving at 5-7 feet per second. This innovative basin requires less water weight (by volume) in the tower system, meaning there is less water to treat, and it is a cleaner system less susceptible to bacterial growth. Tower Tech towers are TSE/RO friendly and can withstand the corrosive conditions of saltwater. They also have a very good impact on increased cycles of concentration; running at higher cycles of concentration (one to two times higher) means less water bleeds off through the HVAC system, saving both water and up to 40% of treatment chemical costs.

Beyond water volume, the FlowThru basin is essentially a clean, fast-flowing stream that doesn’t allow solids to filter out. Not only does this type of basin use substantially less water than a conventional cooling tower’s sediment basin, but it also avoids many of the health hazards associated with open basins. The enclosed, fast-flowing basin prevents sediment and dirt accumulation and avoids the growth of algae and other biofilms that can support Legionella growth. The FlowThru basin has a reduced evaporation percent at part-load, keeping potentially toxic cooling tower droplets away from the outside world, and it has a near-zero decibel level from water noise, unlike the around 10 decibels of competing, open-basin towers. (For reference, the largest waterfall at Niagara Falls is 95 decibels.)

We cannot take water for granted or treat it as an unyielding resource. Investing in a Tower Tech modular tower with a FlowThru basin saves water and money and protects from sediment, Legionella growth and harmful drift. Download our comparison chart to see the differences for yourself, and contact CCG today to discuss how a Tower Tech tower can benefit you.