But redundant can also mean “able to be omitted without loss of function.” That’s exactly what you get inside a Tower Tech modular cooling tower.

With up to twelve, smaller fans inside instead of one or two, Tower Tech towers can stay up and running even when malfunctions happen or when maintenance is needed. Constant uptime better protects mission-critical operations like healthcare facilities, data centers, schools and more.

What’s Inside a Conventional Cooling Tower?

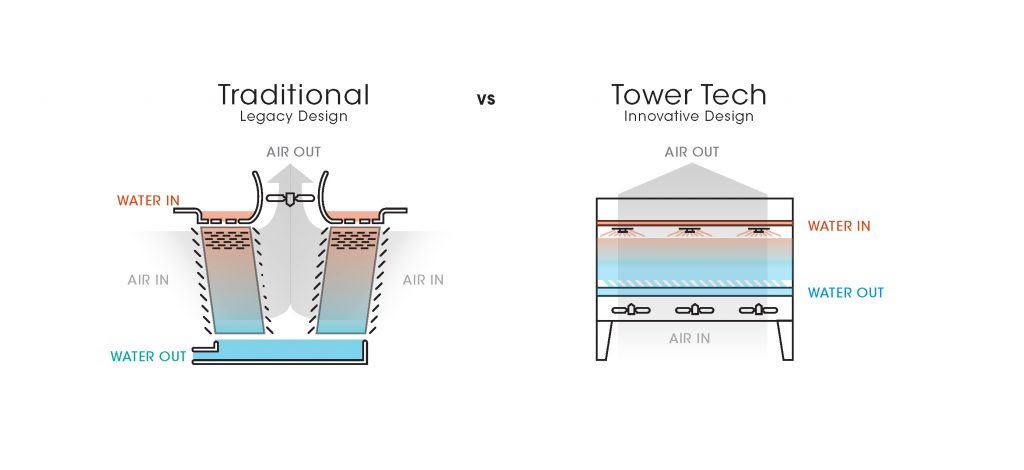

Inside a conventional tower is one to two large fans, each with up to 200 horsepower (hp) each, located at the top of the tower to pull ambient air up through the tower.

The single fan and its location create ideal conditions for catastrophe. An untimely failure can shut down or significantly reduce plant production and can cause buildings to lose valuable cooling capacity during hot summer months, among other problems.

If the tower loses a gearbox, throws a fan blade or burns a belt, the entire cooling tower goes down and stays offline until the equipment can be replaced. Because the fans are at the top of the tower – up in the air – a crane is usually needed to lift and replace the mechanical equipment in the air. Not only does this cause significant downtime, but it also presents an added expense to companies and an added danger to workers.

What’s Inside a Tower Tech Modular Cooling Tower?

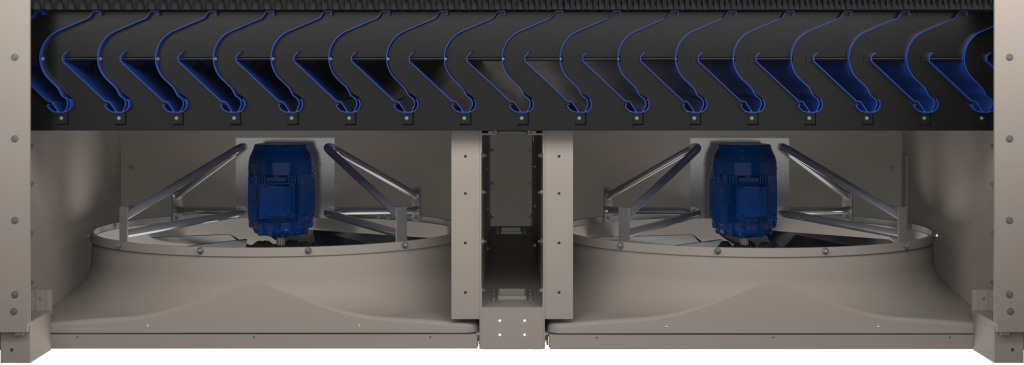

Inside a Tower Tech tower is a matrix of fans. Between two and twelve motors, each 3, 5 or 7.5 hp, blowing air through the tower from the bottom of the unit.

There are three things that set a Tower Tech fan setup apart: number, power and location.

Number: Tower Tech cooling towers use more than double the number of fans as a conventional tower. Even if one goes offline, the remaining fan motors continue running. While one part of the tower will be out of airflow, the majority continue working – even when service technicians work to replace the fan in less than one hour.

Power: Using smaller direct-drive motor fans brings the dual benefits of lightweight and better energy use. In under one hour, two technicians can simply lock-out and tag-out one of the small motors in a Tower Tech tower for replacement as the rest of the fan matrix remains operational. The variable speed drive that runs all cooling tower fans at the desired speed/hertz needed to maintain a specific water temperature can control the power these smaller fans use. The fan speed can be reduced to near zero to prevent fan cycling and over-cooling of the process water. This saves power.

Location: Tower Tech fans are located on the bottom of the cooling tower. This innovation turned the cooling tower world upside down, literally. Putting the fans on the bottom of the tower keeps the fans in the cool dry inlet air stream and away from the highly corrosive environment inside the tower. It also helps Tower Tech towers achieve an industry-leading 0.0004% drift rate by reducing the air velocity at the drift eliminator. The bottom-mounted fans also protect technicians from the dangers of cranes or scaffolds, creating a much safer working environment.

What This Means for Mission-Critical Industries

The risks of NOT being redundant are exceptional. Cooling tower downtime can risk business operations and quickly rack up substantial financial losses. And beyond physical discomfort, loss of cooling can sometimes cost lives. For example:

- A data center’s cooling tower loses a blade and shuts down. The center overheats, resulting in a catastrophic data loss event.

- An industrial plant’s tower motor fails, causing a plant shutdown, with each hour costing half a million dollars in lost production.

- An elementary school’s cooling tower fan needs repair in the heat of back-to-school weather in late August. Because the tower is on the school roof and the fans are on the top of the tower, special equipment must be brought to the site before maintenance can even begin, while the young students inside swelter.

- A hospital, surgical center or nursing home loses cooling. If out too long, the unthinkable may happen to the vulnerable occupants of these buildings.

For mission-critical operations, redundancy is imperative. Tower Tech cooling towers can save CAPEX dollars by providing redundancy in a single unit’s base operating load parameters, which would require multiple conventional towers. Tower Tech cooling towers also save OPEX dollars by providing near-constant uptime, even during maintenance. Contact Tower Tech today to discuss your mission-critical cooling needs and to start your custom PACE savings report today.